Who We Are

Designers, Engineers and Manufacturers of Metal Fabricated Products.

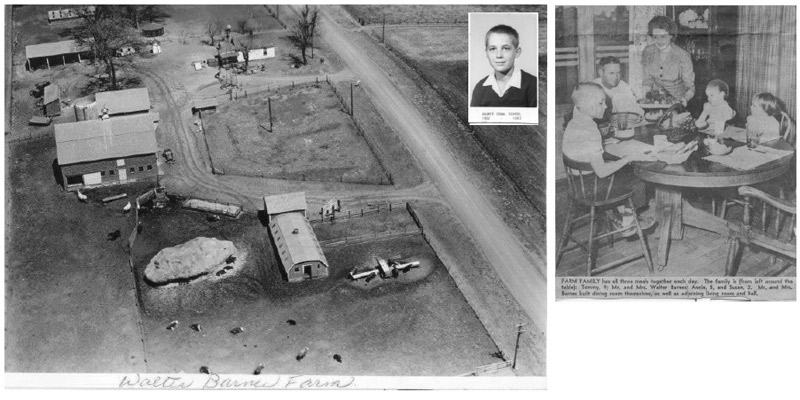

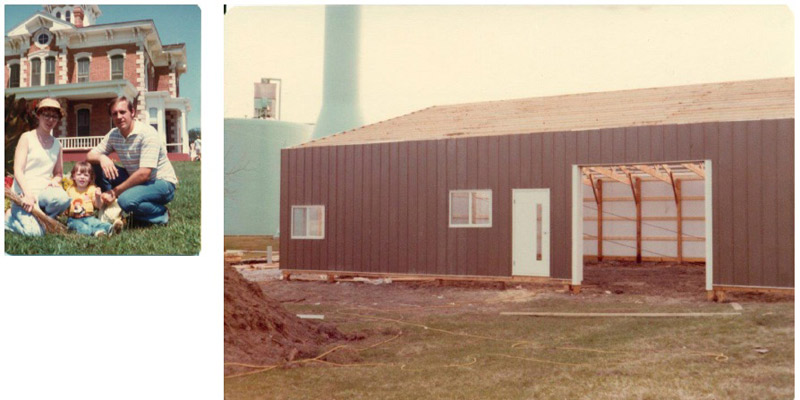

Since 1978, Barnes Manufacturing Services has been solving manufacturing challenges for engineers and designers. Many of us grew up working on projects in the garage or fixing equipment out in the field. We love working with industry partners and in our community- whether that community is local or international, we value our relationships.

What We Do

Throughout our 4 decades, Barnes Manufacturing Services has worked on amazing projects across industries. We have made parts for dump trucks and research satelites, from dime-sized laser optics to elephant-sized castings. Whether you need one part or a thousand, we can partner with you to advance the industry of creating and making.

Capabilities

- Parts and Machine Design Consultations

- Metal Product Prototyping

- Obsolete parts remanufacture

- Custom Fabrication and Custom Manufacturing

- Precision Machining

- Welding Services

- Multi-Process Manufacturing

- Sandblasting and Zinc Thermal Spraying

- Electrical Wiring

- Hydraulic Components

- Powder Coating Services