A Dynamic and Flexible Machining Staff

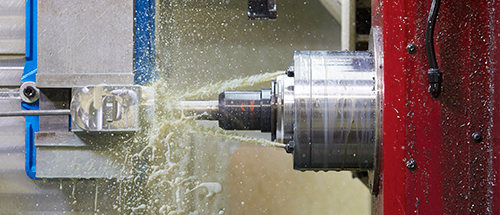

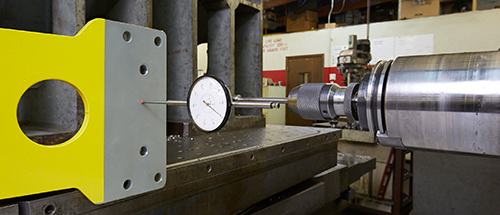

Every one of the engineers, machinists and assemblers at our machine shop use their problem solving skills to ensure your metal parts and CNC machining projects are delivered on time and at the best possible quality. We will help you work through questions like the best angles to use on a part, the right materials for custom fabrication based on the product’s uses, or navigate materials availability and cost to keep your project on budget.

- Industrial Technologists Metal Product Designers

- CNC Machinists

- Welding Services

- Parts Assemblers

- Powder Coat Painters

- Hydraulic Components

- Powder Coating Services

Whether your metal fabrication project requires one of these services or almost all of them, we are up to the task of completing it when you need it and to the quality that you expect.

Top Quality Short-Run Production

Whether you need one metal part prototype, a few custom-designed or retrofitted parts, or a run of 100 metal components, we are happy to help. You can count on us to custom manufacture the parts you need on-deadline every time.

Collaboration for a Better Result in Manufacturing

Our commitment to our customers is based on partnership. The best time to “Bring in Barnes” is during the planning stage of your project – to help you identify the right questions to ask when it comes to manufacturing, machining, buildability or budget concerns. That said, we can assist during any part of your project. Not only does our manufacturing team collaborate with each other for the best possible results, but also with you and your other vendors – in order to ensure you will get the functionality you need out of whatever our machine shop is producing for you.

Size Doesn’t Matter – Metalwork from Miniscule to Massive

From metal parts the size of a penny to large machines, complete with electrical and hydraulic capabilities, our crew will create a plan and use all the best processes to fabricate a quality working product.

With a spacious and well-planned manufacturing facilities, we have ample room for manufacturing, assembly, and finishing your large-scale metal structures and extra-large machines. Some examples of a large fabrication and assembly project is the Klopfenstein Amphitheater for the Performing Arts at Lowe Park in Marion, IA and the reconstruction of the Iowa State Campanille. Separate from large monolithic structures, small metal parts and multi-process components are integral work we can do for you.

You Dream It, Our Engineers, Fabricators and Machinists Can Build It

In an “Agile Manufacturing Environment” it is not necessary, and is often a competitive burden, to own the resources necessary to create, make, sell, and support goods and services. For successful results, it is necessary that companies participating in projects be able to work together intensively, at all levels and in all required roles, accepting shared responsibility for successfully exploiting market opportunities

“No” isn’t in our vocabulary! The scope of your metalwork or machining project will not deter us, and because we love a good challenge, you can count on us to make even the roughest drawing that you dream up into a real, usable part or machine.

- Parts and Machine Design Consultations

- Metal Product Prototyping

- Obsolete parts re-manufacture

- Custom Fabrication and Custom Manufacturing

- Precision Machining

- Welding Services

- Multi-Process Manufacturing

- Sandblasting and Zinc Thermal Spraying

- Electrical Wiring