Continued:

Horizontal Bars

4″ – table 48″ x 60″

w-36″, x-48″, y-60″, z-48″

DRO all four axes 0.0005

- CNC 4″ – table 48″ x 60″

- w-28″, x-82″, y-64″, z-54″

- Horizontal Mills Travels

- 10″ x 28″ w/ 0.0005 DRO

- 10″ x 30″ w/ 0.0005 DRO

- 8″ x 24″ w/ 0.0005 DRO

- Horizontal Production 10″ x 30″

- Vertical Travels

- 8″ x 24″ w/ 0.0005 DRO

- 10″ x 28″ w/ 0.0005 DRO

- (2) 12″ x 30″ w/ 0.00025 DRO

- CNC

- (2) x-30″, y-16″, z-14″

- (2) x-30″, y-14″, z-12″

- x-84″, y-32″,z-30″

- EDM – Wire

- (2) Agie 9″ x 18″ X 4″ thick

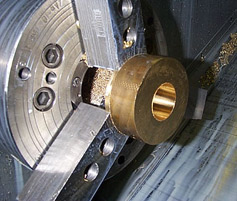

- Lathes

- CNC

- Engine

- 10″ x 32″

- 13″ x 30″ w/ 0.0005 DRO

- 14″ x 48″ w/ 0.0005 DRO

- 25″/16″ x 120″ w/ 0.0005 DRO

- 36″ x 8″ Tee

- Turret

- Saws

- Horizontal 10″ x 16″

- Vertical 10″ x 16″

- Cold 2″ diameter

- Drills

- Upright

- 14″ x #3 MT

- 12″ x #4 MT

- 10″ x #2 MT

- Traveling Column 72″ x 180″ #5MT w/ Digital Readouts

- 4 Spindle 10″ x #2 MT

- 18 Spindle – MultiRadial 36″ x #4 MT

- Auto – Tapper Cap. 3/8″

- Key Seating

- Polisher

- Grinders

- Cylindrical

- Surface

- 6″ x 12″ x 12″

- 6″ x 14″ x 18″

- 7″ x 12″ x 18″

- 12″ x 12″ x 40″

- Head Surfacer

- Tool & Cutter Cincinnati #1

- Furnaces

- Heat Treating

- 6″ x 5″ x 9″

- 6″ x 10″ x 18″

- 15″ x 16″ x 17″

- 22″ Dia. x 30″

- Carburizing

- 10″ Dia. x 18″

- 24″ Dia. x 30″

- Presses

- 20 Ton OBI

- 20 Ton Straight Side

- 5 Ton Arbor

- Inspection

- Bench Centers – 6″ x 18″

- Cadillac Height Gage – 24″ & 48″

- Electronic Indicators – 0.000050

- Hardness Tester Wilson – #4TT – RB

- Optical Comparator – 2″ x 6″

- Coordinate Measuring Machine 12″ x 18″ x 24″

- Surface Plates

- Hoists

- Fork Trucks

- Delivery Trucks

[Not a valid template]

Summit Boring Mill

Huge Travels

x = 78″

y = 65″

z = 27-1/2″

w = 62

- Precision ground ballscrews

- Steel inserted ways

- 4-axis digital readout

- Built in rotary table

- Way covers on horizontal ways

- “State of the art” electrics & hydraulics

- 3 axis point to point control

- Linear scale feedback

- Hydraulic clamping

HAAS Lathes

Haas HL-4 Lathe

Turning Diameter: 14.5″

Turning Length: 34″

- Brushless Servo Motors

- Rigid Cast Iron Construction

- Unique Torque-Tube Bed Design

- Double Anchored Ballscrews

- Direct-Coupled Servo Motors

- 30 hp Spindle

- 5″ Bar Capacity

- 12 Turret Positions

- 10″ Chuck

- Made in USA

Haas VF-1B Mill

Huge Travels

x = 20″

y = 16″

z = 20″

Like every Haas machine, the VF-1 represents years of on-going refinement. Customer feedback coupled with a relentless pursuit of perfection sees advancements and design enhancing changes incorporated directly into the production line every day. The Haas VF-1 is a rugged, small-footprint VMC that yields reliability and accuracy in a small-framed machine.

The VF-1 has a 40-taper cartridge spindle that’s powered by a 20 hp motor driving through the Haas 2-speed geared head. The VF-1 will produce 250 ft-lb of torque at a low 450 rpm, but will also run up to 7,500 rpm in less than 5 seconds for finishing aluminum.

Haas VF-7 Mill

Huge Travels

x = 84″

y = 32″

z = 30″

Table Size

x = 84″

y = 28″

Features:

- Rigid, Cast-Iron Construction

- Double Anchored Ballscrews

- Direct-Coupled Servo Motors

- Hardened-Steel Bearing Packs

- Dual, 32-Bit Processors

- Word Processor Editing

- One-Button Features

- 100% Ball Bar Tested

- 20 Pocket Tool Changer

- 2-Speed Gearbox – 7500 rpm

- 250 ft-lb. of Cutting Torque

- Vector Drive

- 20-hp Spindle

- Brushless Servo Motors

- 710-ipm Rapids

- Made in the USA

HAAS TM-1 Mill

Travels

x = 30″

y = 12″

z = 16″